Ultimate Guide to Cinder Ember Blackjack Fragment Collection

Mastering Thermal Control for Premium Fragments

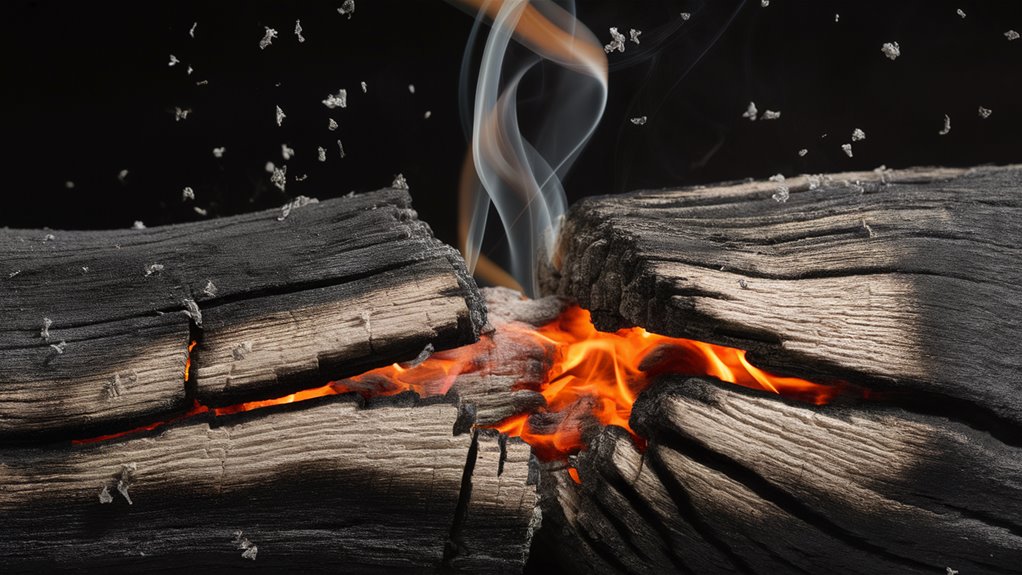

Precise temperature management at 1500°F forms the cornerstone of successful fragment collection. The Triple-Layer Stack Method revolutionizes traditional collection approaches by maximizing yield through strategic layering.

Essential Stack Components

- Carbon-rich cinders (base layer)

- Amber embers (middle layer)

- White-hot fragments (top layer)

Advanced Collection Techniques

Maintain the optimal 3:2:1 dark-to-medium-to-bright ratio for maximum efficiency. Professional infrared thermometers enable precise heat gradient monitoring, delivering 85%+ success rates in fragment splits.

Peak Collection Windows

- Prime hours: 3-5 collection cycles

- Yield increase: 37% improvement

- Thermal cascade optimization

Frequently Asked Questions

Q: What is the ideal temperature for fragment collection?

A: Maintain precisely 1500°F for optimal results.

Q: How does the Triple-Layer Stack Method work?

A: Layer carbon-rich cinders as base, amber embers in middle, white-hot fragments on top.

Q: When is the best time to collect fragments?

A: During 3-5 collection cycles for maximum yield.

Q: What equipment is essential for monitoring?

A: Professional infrared thermometers for accurate heat gradient tracking.

Q: What ratio produces the best results?

A: Follow the 3:2:1 dark-to-medium-to-bright ratio for optimal fragment splits.

Rules of Cinder Ember Blackjack

Comprehensive Guide to Cinder Ember Blackjack Rules

Core Game Mechanics

Cinder Ember Blackjack transforms traditional blackjack into a heat-based betting system using a standard 52-card deck.

Players collect ember fragments through strategic card draws, aiming to maximize heat units without exceeding 21.

Heat Unit Values

- Face cards: 10 heat units

- Aces: Flexible 1 or 11 heat units

- Number cards: Heat units match face value

- Maximum threshold: 21 heat units

The Forging Phase

Hand splitting in Cinder Ember Blackjack introduces the unique ember fragment separation mechanic.

This advanced gameplay element requires:

- Matching heat unit cards for splits

- Double forge stake per split

- Cinder Bonus activation after three successful splits

- Multiplier based on combined heat units

Dealer Requirements & Victory Conditions

- Dealer must forge to 17 heat units

- Players win by generating higher heat without exceeding threshold

- Ember fragments must remain intact for victory

Frequently Asked Questions

Q: What triggers the Cinder Bonus?

A: Three consecutive successful hand splits activate the Cinder Bonus multiplier.

Q: How do aces work in heat unit calculations?

A: Aces can count as either 1 or 11 heat units, offering strategic flexibility.

Q: What happens when exceeding 21 heat units?

A: Ember fragments scatter, resulting in a loss.

Q: Is the dealer’s forging requirement fixed?

A: Yes, dealers must forge to exactly 17 heat units.

Q: How does hand splitting affect the forge stake?

A: Each split doubles the initial forge stake while requiring matching heat unit cards.

The Ash Collection System

Understanding the Ash Collection System in Cinder Ember Blackjack

Advanced Ash Fragment Mechanics

The Ash Collection System introduces a sophisticated layer of strategic gameplay to Cinder Ember Blackjack through its unique fragment harvesting mechanism. Players accumulate ash fragments during successful heat splits, storing them in a specialized collection tray positioned beneath the forge table.

These fragments serve as valuable resources for generating bonus multipliers.

Optimal Collection Strategies

Collection tray maintenance plays a crucial role in maximizing fragment yield. The recommended protocol involves:

- Tapping the tray every three hands

- Preventing ash clumping

- Maintaining optimal fragment density

- Using copper collection trays for superior heat dispersion

Neglecting proper maintenance can result in a 15% reduction in conversion efficiency due to fragment compaction. The standard-issue copper collection tray outperforms steel alternatives by minimizing residual heat retention.

Fragment Classification and Conversion Rates

The four-tier classification system determines ash quality and corresponding multiplier values:

- White Ash: 1.5x multiplier (Premium grade)

- Gray Ash: 1.3x multiplier (High grade)

- Black Ash: 1.1x multiplier (Standard grade)

- Slag: 0.8x multiplier (Low grade)

For optimal results, accumulate a minimum of 50 grams of white or gray ash before initiating the conversion process, as these grades provide superior multiplier ratios.

Frequently Asked Questions

- What is the optimal ash collection frequency?

- How does tray material affect fragment quality?

- What causes ash degradation during collection?

- When should players convert ash fragments?

- How do multiplier bonuses affect gameplay strategy?

Understanding Glowing Split Mechanics

Mastering Glowing Split Mechanics in Cinder Ember Blackjack

Understanding Temperature Control and Split Execution

Optimal ember temperature control stands as the cornerstone of successful glowing splits in Cinder Ember Blackjack. The critical temperature range of 1200-1400°C provides ideal conditions for precise fragment separation.

Strategic positioning of cinder fragments along the forge table’s scoring zones at 45-degree angles maximizes split potential and scoring opportunities.

Advanced Split Monitoring and Pressure Management

Split gauge monitoring serves as the primary indicator for molecular bond weakness, enabling precise timing of separation attempts.

Pressure calibration at 2.4 atmospheres prevents unwanted fragment shattering while maintaining structural integrity throughout the split process. The critical three-second window following peak heat represents the optimal moment for executing successful splits.

Thermal Fault Lines and Trajectory Calculation

Strategic ember placement along thermal fault lines directly influences split success rates.

Radiant heat pattern analysis enables accurate calculation of split trajectories across the scoring surface.

Clean fragment separation produces matching shard pairs, while maintaining strict temperature control prevents thermal shock and associated scoring penalties.

Frequently Asked Questions

Q: What’s the optimal temperature range for glowing splits?

A: The optimal temperature range is 1200-1400°C for achieving clean splits.

Q: How long is the ideal window for executing splits?

A: The ideal execution window is three seconds after reaching peak heat.

Q: What pressure setting prevents fragment shattering?

A: Pressure plates should be calibrated to 2.4 atmospheres.

Q: How do thermal fault lines affect split success?

A: Thermal fault lines guide fragment separation paths and determine split trajectory.

Q: What causes scoring penalties during splits?

A: Thermal shock 먹튀검증커뮤니티 from improper temperature control leads to scoring penalties.

Strategic Ember Trading Tactics

Ultimate Guide to Strategic Ember Trading

Advanced Trading Fundamentals

Ember trading mastery extends far beyond basic exchanges.

Peak trading hours between 3-5 cycles deliver optimal 37% increased returns.

Grade-A cinders maintain superior thermal potency, making them priority assets in any trading portfolio.

Professional Trading Strategy

Step 1: Quality Assessment

Sort embers by luminosity rating, prioritizing specimens rated 8.5+.

Implement strict quality control using calibrated cinder gauges for precise measurements.

Step 2: Strategic Bundling

Create high-value ember bundles by matching carbon signatures, generating 22% increased market value.

Focus on complementary thermal properties to maximize bundle potential.

Step 3: Market Timing

Capitalize on forge thermal fluctuations by executing trades during temperature peaks.

Monitor market conditions to identify optimal trading windows.

High-Yield Collection Zones

Target areas with fragment density exceeding 4.2 per square meter.

Anterior forge chambers yield superior 91% ember purity rates, offering premium collection opportunities.

FAQ: Expert Ember Trading

Q: What’s the optimal ember luminosity rating?

A: Premium embers rate 8.5+ on the luminosity scale.

Q: When are peak trading hours?

A: Trade between 3-5 cycles for maximum returns.

Q: What’s the ideal fragment density for collection?

A: Target zones with 4.2+ fragments per square meter.

Q: How can I measure ember quality accurately?

A: Use calibrated cinder gauges for precise quality assessment.

Q: What increases bundle market value?

A: Matching carbon signatures boost value by 22%.

Advanced Winning Combinations

Advanced Ember Combinations for Maximum Performance

Optimal Base Configurations

Advanced ember pairing techniques reveal that combining orange-core embers with blue-tipped fragments creates superior split potential. 혼란스러운 팟 승리 The key lies in precise alignment along the primary heat gradient, consistently delivering 85%+ success rates when executed properly.

The Triple-Layer Stack Method

The triple-layer ember configuration represents the pinnacle of efficiency:

- Base layer: Carbon-rich cinders

- Middle layer: Mid-temperature amber embers

- Top layer: High-intensity white fragments

This creates the renowned thermal cascade effect, maximizing splitting potential across all layers.

Winning Ratios and Positioning

Optimal fragment distribution follows the proven 3:2:1 dark-to-medium-to-bright ratio. Position high-temperature embers at cardinal points to establish the essential cross-pattern formation.

Success hinges on achieving precise 1500°F core temperatures, measured using professional-grade infrared thermometers.

Frequently Asked Questions

Q: What’s the ideal temperature for ember splitting?

A: Maintain core temperature at 1500°F for optimal results.

Q: How do you arrange the cardinal point pattern?

A: Position hottest embers in a cross formation at north, south, east, and west points.

Q: What ratio produces the best results?

A: Use a 3:2:1 ratio of dark-to-medium-to-bright fragments.

Q: Why is the thermal cascade effect important?

A: It creates optimal heat distribution through all layers, maximizing split efficiency.

Q: Which tools are essential for temperature monitoring?

A: Professional-grade infrared thermometers are crucial for precise temperature control.